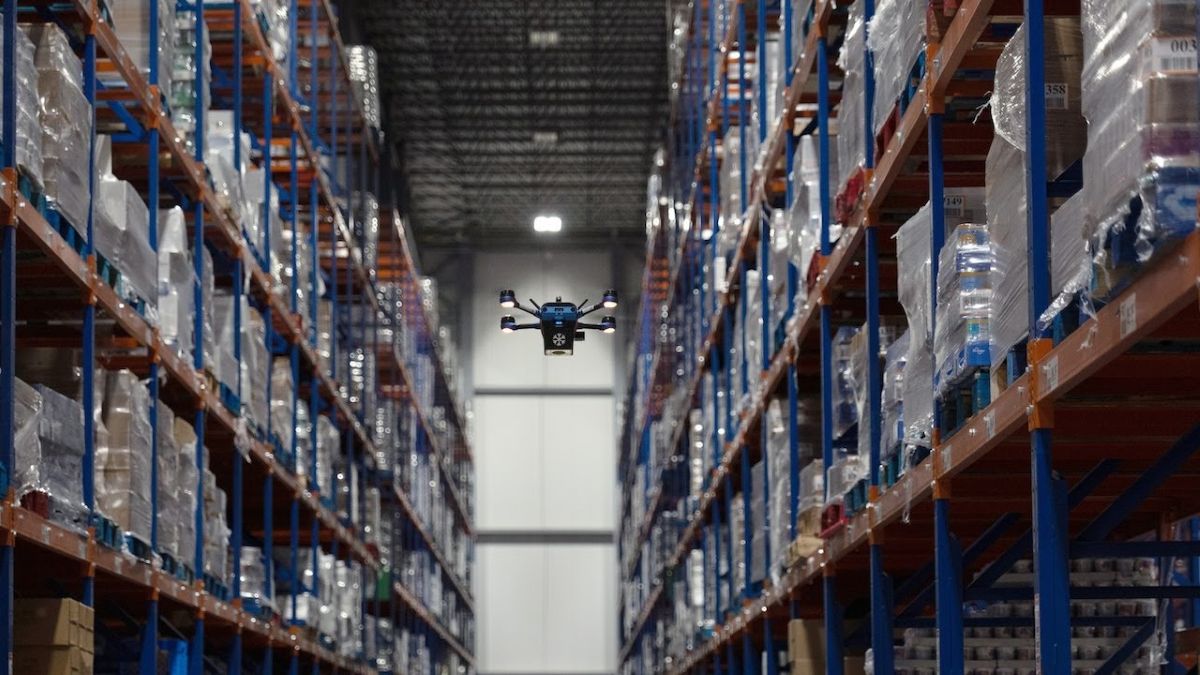

Warehouses built for frozen food aren’t exactly friendly places for people, or robots. Temperatures plunge well below zero, frost builds up on everything, airflow is constant, and visibility can be a mess. Yet these same environments demand some of the most precise inventory tracking in logistics. That’s the problem Corvus Robotics says it has cracked with the launch of Corvus One for Cold Chain, a drone-based inventory system designed to operate autonomously in freezer warehouses as cold as minus-20 degrees Fahrenheit.

At its core, Corvus One for Cold Chain is about keeping humans out of the cold while keeping inventory data accurate and current. Instead of sending workers into sub-zero aisles for manual cycle counts — often in short, gear-heavy shifts — the system flies on its own, scanning pallets and barcodes continuously. The result is near real-time visibility into what’s in the freezer, where it’s located, and how long it’s been sitting there.

That’s easier said than done. According to Jackie Wu, most automation simply isn’t built for freezer conditions. Extreme cold, condensation, glare from ice, and powerful blowers can all throw off sensors and destabilize flight. Corvus says it had to rethink everything from thermal management to perception and flight control to make the system reliable in these environments.

The payoff is a drone that can keep flying and scanning even when conditions would normally shut automation down. Corvus One for Cold Chain uses industrial-grade barcode scanners with precise control over focus and exposure, allowing it to read labels that are frosted over, low-contrast, or partially damaged. Stabilized flight helps the drone compensate for airflow from freezer blowers and doors opening and closing, so normal operations don’t have to stop just because an inventory scan is happening.

New: Drone busts Wisconsin woman for repeated park pooping

One major US retailer is already putting the system to work. Kroger is using Corvus One for Cold Chain in live freezer operations, where the drones are reducing the need for manual cycle counts while delivering consistent inventory visibility. For large grocers dealing with thousands of frozen SKUs, that kind of insight can make a big difference.

Frozen inventory is notoriously hard to manage. Products often have shorter shelf lives, strict FIFO (first in, first out) requirements, and growing SKU counts driven by consumer demand. Missing or outdated inventory data can quickly turn into write-offs or out-of-stocks. By performing frequent, fully autonomous cycle counts, Corvus One helps operators track pallet positions and dwell time more precisely, improving replenishment accuracy and space utilization inside crowded freezer warehouses.

There’s also a labor angle that warehouse operators can’t ignore. Freezer work is expensive and physically demanding, requiring specialized clothing, limited exposure windows, and shorter shifts. Automating routine inventory counts means fewer trips into the cold, lower labor overhead, and improved worker safety — all without sacrificing data quality.

Another key selling point is how little the system asks from the facility itself. Corvus One for Cold Chain doesn’t require Wi-Fi, special lighting, localization markers, or custom barcodes. It’s designed to fly autonomously during active shifts, adapt to changing airflow, and manage its own uptime through automated battery swaps and health monitoring. All of this is delivered under Corvus Robotics’ Robots-as-a-Service model, which bundles hardware, software, and ongoing operation into a single offering.

As cold chain operations continue to expand across grocery, food service, and pharmaceuticals, the pressure to maintain perfect inventory accuracy isn’t going away. Corvus is betting that purpose-built drones, designed from the start for harsh freezer conditions, can finally make autonomous inventory a practical reality where traditional automation has struggled.

More: DJI’s SkyPixel contest shows how far drone storytelling has come

FTC: We use income earning auto affiliate links. More.

Comments